These 5 Golden Rules of Electrical Safety for emphasise the importance of isolating power sources and ensuring that there is no electrical energy present (often referred to as zero energy), preventing accidental reconnection, testing for volta

ge with a metre, grounding devices, and clearly marking unsafe areas.

Adhering to these principles can significantly reduce the risk of electrical accidents. Regular maintenance, inspections, and the proper use of electrical equipment are crucial for creating a safe electrical environment.

This is also an opportune moment to check for any electrical hazards, such as frayed cords or worn wires. Taking these precautionary measures can help individuals establish a safer electrical space for themselves.

Golden Rules of Electric Safety are the 5 crucial tasks that will help you to maintain electrical safety for users and properties.

What Are the 5 Golden Rules of Electrical Safety

Understanding Electrical Safety

Electrical safety protects people, property and electrical systems from possible danger. We can minimize the risk of an accident by following five golden rules of electrical safety. These basic rules are a generalization that helps homeowners and professionals alike stay safe when dealing with electricity.

First Golden Rules of Electric Safety is, always ensure power has been disconnected before carrying out any electrical work – be it a repair, installation or maintenance task. It is this simple but important step that also keeps you and those technicians at risk of falling into electrical fires from electrocution. Secondly, getting the right kind of tools and gears are necessary.

Using more specific electrical tools, including insulated screwdrivers and pliers greatly minimizes the danger of electric shocks.

Third, water is a killer when it comes to anything electrical. So never work on electrical systems when they are wet or damp. Water is a conductor of electricity so this increases the risk of accidents. It is, therefore, advisable to delay electrical work until the conditions are dry. Fourth, periodic inspection and maintenance of electrical installations is necessary to detect and eliminate future hazards. Routine inspections allow you to catch any defective wiring, outlet damage or other electrical issues that may become a hazard.

Finally, it is strongly recommended to hire professionals for tedious electrical works. If it is a complex electrical issue, then you should let professional electricians with license carry this out as they have the experience and skills to perform this without danger.

If we strictly adhere these five golden rules, than we all can help to create safer electrical environment to protect ourselves and others from harm.

The 5 Golden Rules of Electrical Safety

5 golden rules of electrical safety are the foundation of electrical safety. Well grounding is good practice because it means any electrical charge will be properly dispersed into the earth, reducing the chance of electric shock.

Using safe circuit installations like using wire and other elements as per specifications, correctly installing the required circuit breaker etc. avoids any chances of an over-loaded circuit or short-circuit Scheduled maintenance and inspection of electrical systems and equipment detect potential hazards and correct them before an accident occurs.

Using electrical equipment appropriately (not overloading outlets, using appliances for their intended purposes) also limits the chances of electrical fires and malfunctions. Finally, knowing about electrical hazards such as recognising faulty wiring and the risk between water and electricity, assits people in preventing accidents.

And here are the 5 golden rules for staying safe so you can reduce electrical accidents to a minimum in your own home or workplace.

Rule 1: Disconnect and Verify

Safety is always important, so before working on any electrical items, be sure to turn off the power.

This is an important step because electric shock, a deadly risk, is now unlikely to happen. Before starting any work, however, it is critical to confirm that the system has been completely de-energized. We can prove that by running some proper testing equipment that there is no electrical current.

These precautionary steps will help maintain the safety of you and others against electrical work hazards. Better safe than sorry, so always be cautions even if you want to save few seconds.

Rule 2: Prevent Reconnection

It is therefore vital to ensure the security of work, so that it does not accidentally reconnect. Physically isolate secure devices, such as circuit breakers and switches, with locks and keys.

It makes unauthorized access and accidental re-energization impossible. There should be clear signage (e.g. an isolation sign or the equivalent) indicating to others that the area is in isolation. Testing must be done to ensure the isolation is correct before starting any work.

This will involve using voltage indicators/instruments to ensure there is no electrical current flowing.

Following these recommendations will greatly decrease the chances of electrical shock and help by creating a safer working environment.

Rule 3: Check for Voltage

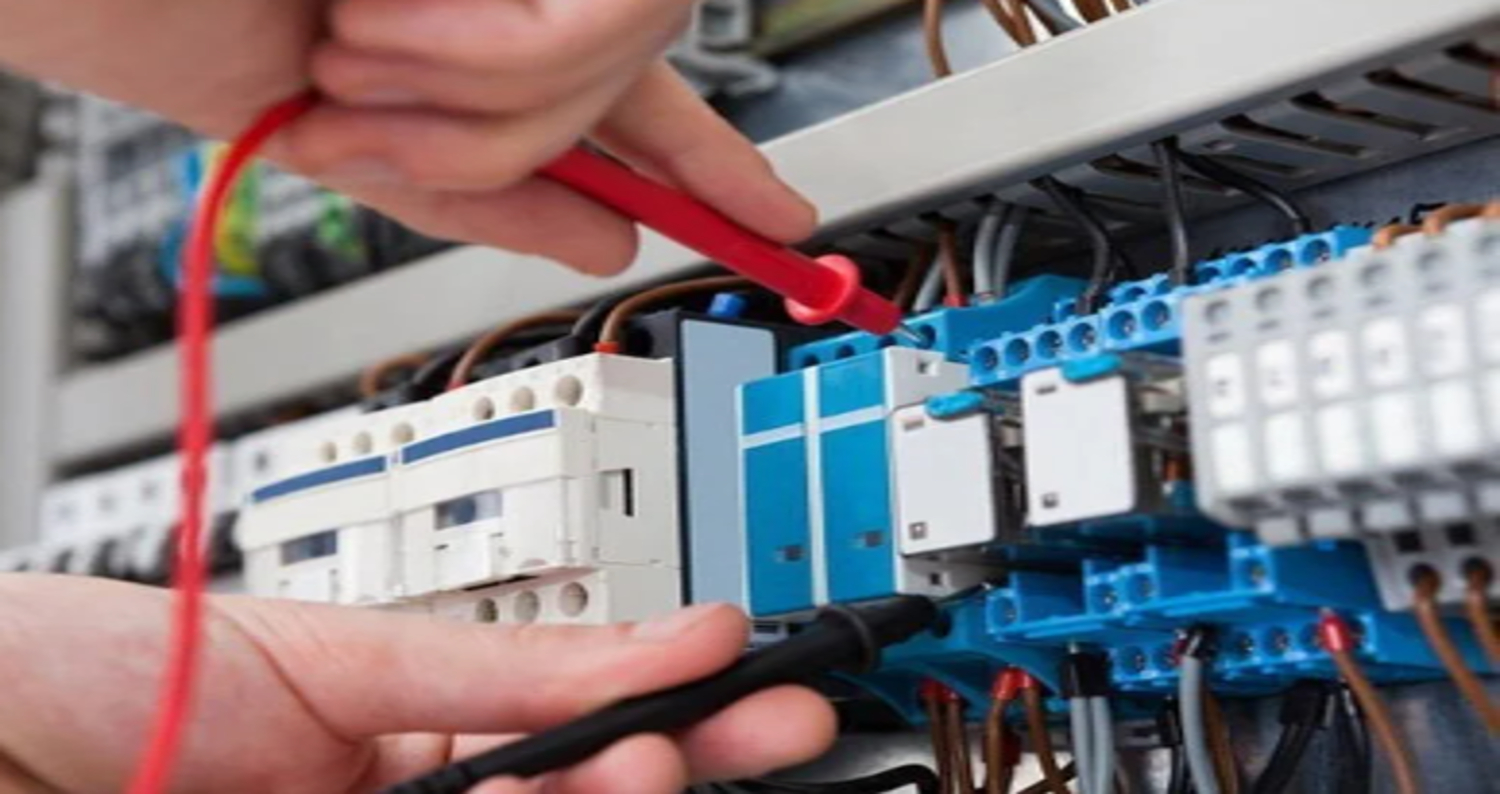

Getting started with all the electrical work can be extremely dangerous, so safety comes first on this list. One a very important first step is to check that there is no voltage with an appropriate voltmeter.

It makes sure that the current is not live, so that there is no risk of electric shock to the technician. After confirmation, the next step is to prove that it is correct isolation.

setting an earth do this is on the circuit, shorting any energy remaining.

This method successfully de-energizes the circuit to reduce potential hazard from inadvertent electrical surges. It also reduces risk of shock by ensuring that all conductors are at the same potential as each other and that of the technician.

If technicians properly follow these basic safety procedures, then not only will they be able to work more confidently, but it will also lessen accidents and contribute to safety in the workplace.

Rule 4: Ground the Installation

We cannot overstate the importance of grounding electrical installations. This acts as a safety feature that protects the users from electric shock. Grounding provides a low-resistance path for electrical current to flow into the earth, effectively balancing out anything that may become hazardous due faults or surges.

Grounding provides the way to safely channel excess electrical energy away from the electrical system into the ground, protecting against surge or grounding. This protects the installation and its users alike. Grounding also serves as a voltage stabilizer, which will allow stable and reliable electrical performance.

Rule 5: Cordon Off the Area

It is the best practice to restrict area around downed powerlines to ensure public safety. One way to keep people out of the danger zone is to use proper signage and physical barriers.

You need to be far away from the power lines because touching them can cause electrical shock.

The risk should have visible signage highlighting the presence of high voltage. Following these precautions can reduce many times the chance of an accident occurring and save lives.

Implementing Electrical Safety Guidelines

Whether it be a house or an industrial complex, electrical safety is the most necessary factor everywhere.

Frequent checking of electrical equipment and systems is important to make sure they are safe. Such forward-looking perspective recognizes dangers like worn-out cables, defective sockets, or congested circuits that could eventually cause accidents.

Also, full-scale training of employees is necessary. Implementing training programmes on electrical safety procedures, protocols and emergency response plans will help an organisation mitigate the risk of electrical shocks, fires and other accidents. A safer environment for all can be achieved with the emphasis on electrical safety by businesses and individuals.

Safe Circuit Installation and Maintenance

Determining the load requirements is an integral part of any electrical setup. It is design to be both safe and efficient. To ensure that the circuit is not overloaded. Accurately calculate amenities total power consumption. Circuit selection — Choose between standard 15–amp or a 20–Amp circuits based on the load.

Installation and Wiring are with the local codes & standard rules Do what is necessary to implement it so that electrical risks are not too easily possible. Check the circuit routinely for any evidence of damage or wear and tear. If you stick to these tips, your electrical system will be reliable and safe.

Safe Use of Electrical Equipment

To ensure safety when using electrical equipment, it’s crucial to understand its capabilities and limitations. Always follow the manufacturer’s instructions and adhere to safe operating practices. Keep your hands dry when handling electrical devices, as moisture can increase the risk of electric shock.

Regularly inspect cords for damage and avoid using equipment with frayed or exposed wires. Be mindful of overloading outlets, as this can lead to overheating and potential fires. If you encounter any electrical issues, consult a qualified electrician to prevent accidents and ensure proper functioning.

Identifying and Preventing Electrical Hazards

Electrocution is one of the most dangerous hazards in any workplace. Regular inspection of electrical equipment and wiring is important for any working environment to be safe.

Examine cords and cables for damage or wear that could cause electrical shocks or fires. Also have all the electrical appliances wired so that it does not electrocute you. Check insulation on cables and equipment for wear. If you find anything wrong, immediately report it to your supervisor. With these precautionary measures, you will better minimize any potential electrical accidents, making the workplace much safer.

continue reading

Related Posts

By conducting an electrical audit. Building owners can ensure they […]

Conducting an electrical system audit is important for confirming the […]

Electrical safety is the prime factor in any environment where […]